Webtool subsea cutting – technology transfer to Steel Manufacture

In a novel example of technology transfer from the subsea sector to steel manufacturing, ArcelorMittal, one of the world’s leading integrated steel and mining companies, is using Webtool cutting technology during metal extrusion production.

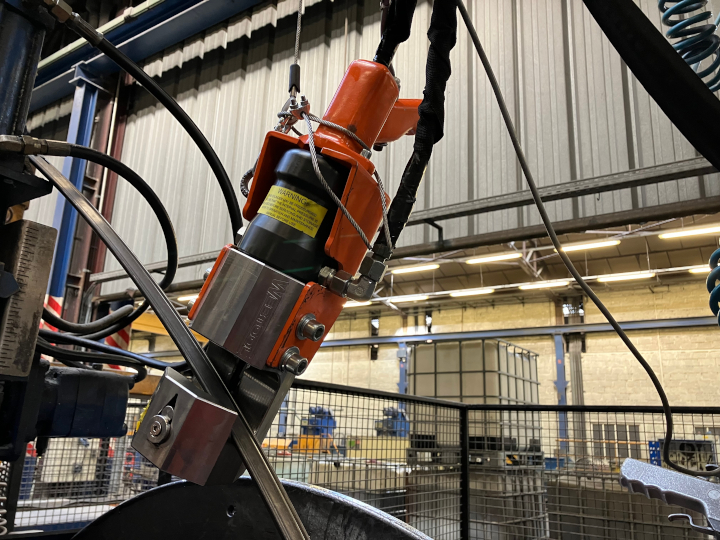

The Webtool RCO40 hydraulic cutting tool has been deployed within a metal extrusion production line to cut overproduced sections down to size ready for recycling. Its open sided design allows easy positioning of the extruded steel as it is channelled through the cutter. The cutter’s blade shaped anvil ensures a smooth and efficient cut.

To customise the cutter still further, engineers at the extrusion facility have fitted the Webtool cutter with a sleek and efficient trigger operation mechanism, making it even more user-friendly and precise. The RCO40 cutter has performed a large number of cuts on a single blade and given ArcelorMittal significant time saving over traditional cutting methods.

“At Webtool, we pride ourselves on the versatility and reliability of our products. Our cutting tools are designed to excel in numerous industries, adapting seamlessly to the unique demands of each application. Whether it’s subsea, construction, or any other sector, Webtool delivers exceptional performance every time,” said Rory McGarry, Engineering Director, Allspeeds.

Webtool cutter for steel extrusion process.

Webtool RCO40 cutter

Weighing 17kg, the Webtool RCO40 is a high pressure, heavy duty wire rope cutter typically deployed subsea in severe working conditions. Constructed in durable stainless steel, the RCO40 cutter’s compact design features mounting holes in the body allow for the fitting of standard handles or bespoke mounting brackets.

All Webtool cutters are designed and manufactured exclusively by Allspeeds Ltd in the UK.